Professional manufacturer and trader of air compressor parts

Whatsapp/Wechat+0086 15137376132

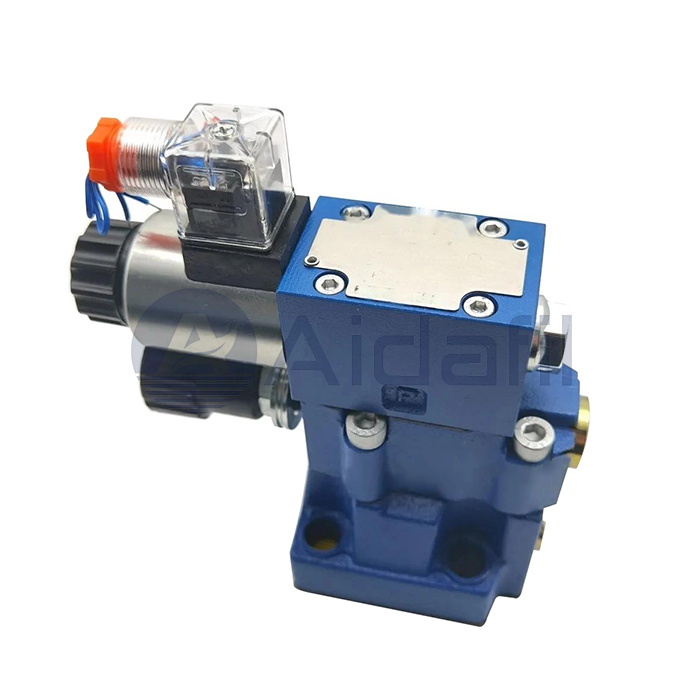

Replacement S10A1

Parts & Accessories

Parts & Accessories

S10A1

(replacement)for Rexroth

Part numbers marked "replacement" are not affiliated with the original manufacture. Part numbers and pictures are used for cross reference only.

- Description

Rexroth Parts & Accessories S10A1 replacement

The check valve, also known as a non-return or one-way valve, is an indispensable part of any pneumatic system, especially those involving air compressors. It is engineered to allow the unidirectional flow of compressed air, preventing backflow when pressure changes or the air compressor stops functioning. The primary purpose of this valve is to maintain system pressure, protect components from damage due to reverse airflow, and improve overall operational efficiency.

The S10A1 check valve for air compressor is a vital component in air compressor systems, designed to ensure the smooth and efficient operation of the system by allowing air to flow in one direction while preventing backflow in the opposite direction.

Functions

The primary function of the S10A1 check valve is to permit the flow of air in one direction only. This unidirectional flow is essential for:

1. Ensuring that the compressed air moves through the system as intended without reversing its course.

2. Preventing contamination by stopping potential backflow of liquids, gases, or solids from entering the air compressor.

3. Maintaining the pressure level within the system for optimal performance.

Additionally, the S10A1 check valve helps to minimize pressure surges that could damage other components within the air compressor system. Its quick response time to changes in pressure further enhances the overall efficiency and safety of the operation.

Features and Design

The S10A1 check valve boasts several notable features that contribute to its effectiveness and reliability:

1. Material - Crafted from high-quality corrosion-resistant materials, the S10A1 check valve can withstand harsh environments and resist wear and tear.

2. Simple yet efficient mechanism - The design includes a spring-loaded poppet that allows for easy opening and closing. When the pressure pushes against the poppet, it opens the valve; otherwise, the spring forces it shut, ensuring no reverse flow.

3. Pressure tolerance - It is engineered to handle a specified range of pressures without failing or allowing leakage.

4. Easy maintenance - Due to its simple design, the check valve can be easily disassembled for cleaning, inspection, and maintenance.

5. Longevity - The robust construction and quality materials ensure a long operational lifespan before requiring replacement.

Benefits

The S10A1 check valve offers several benefits to air compressor systems, including:

1. Preventing backflow - By preventing the reversal of air flow, the S10A1 check valve ensures the smooth operation of the air compressor and other pneumatic devices in the system.

2. Increased efficiency - The S10A1 check valve allows the air compressor to operate more efficiently by preventing the loss of compressed air and minimizing pressure fluctuations.

3. Enhanced safety - The S10A1 check valve helps to maintain the pressure within the system, reducing the risk of equipment failure or damage due to excessive pressure.

4. Reduced maintenance - The S10A1 check valve is designed for durability and corrosion resistance, reducing the need for frequent maintenance and replacement.

5. Compact and lightweight - The S10A1 check valve is designed to be compact and lightweight, making it easy to install and maintain in various applications.

The Parts & Accessories is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our S10A1 Parts & Accessories can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

The check valve, also known as a non-return or one-way valve, is an indispensable part of any pneumatic system, especially those involving air compressors. It is engineered to allow the unidirectional flow of compressed air, preventing backflow when pressure changes or the air compressor stops functioning. The primary purpose of this valve is to maintain system pressure, protect components from damage due to reverse airflow, and improve overall operational efficiency.

The S10A1 check valve for air compressor is a vital component in air compressor systems, designed to ensure the smooth and efficient operation of the system by allowing air to flow in one direction while preventing backflow in the opposite direction.

Functions

The primary function of the S10A1 check valve is to permit the flow of air in one direction only. This unidirectional flow is essential for:

1. Ensuring that the compressed air moves through the system as intended without reversing its course.

2. Preventing contamination by stopping potential backflow of liquids, gases, or solids from entering the air compressor.

3. Maintaining the pressure level within the system for optimal performance.

Additionally, the S10A1 check valve helps to minimize pressure surges that could damage other components within the air compressor system. Its quick response time to changes in pressure further enhances the overall efficiency and safety of the operation.

Features and Design

The S10A1 check valve boasts several notable features that contribute to its effectiveness and reliability:

1. Material - Crafted from high-quality corrosion-resistant materials, the S10A1 check valve can withstand harsh environments and resist wear and tear.

2. Simple yet efficient mechanism - The design includes a spring-loaded poppet that allows for easy opening and closing. When the pressure pushes against the poppet, it opens the valve; otherwise, the spring forces it shut, ensuring no reverse flow.

3. Pressure tolerance - It is engineered to handle a specified range of pressures without failing or allowing leakage.

4. Easy maintenance - Due to its simple design, the check valve can be easily disassembled for cleaning, inspection, and maintenance.

5. Longevity - The robust construction and quality materials ensure a long operational lifespan before requiring replacement.

Benefits

The S10A1 check valve offers several benefits to air compressor systems, including:

1. Preventing backflow - By preventing the reversal of air flow, the S10A1 check valve ensures the smooth operation of the air compressor and other pneumatic devices in the system.

2. Increased efficiency - The S10A1 check valve allows the air compressor to operate more efficiently by preventing the loss of compressed air and minimizing pressure fluctuations.

3. Enhanced safety - The S10A1 check valve helps to maintain the pressure within the system, reducing the risk of equipment failure or damage due to excessive pressure.

4. Reduced maintenance - The S10A1 check valve is designed for durability and corrosion resistance, reducing the need for frequent maintenance and replacement.

5. Compact and lightweight - The S10A1 check valve is designed to be compact and lightweight, making it easy to install and maintain in various applications.

The Parts & Accessories is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our S10A1 Parts & Accessories can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

Related products