Professional manufacturer and trader of air compressor parts

Whatsapp/Wechat+0086 15137376132

Replacement 1614662600

- Home

- Hose assembly

- Atlas Copco

- 1614662600

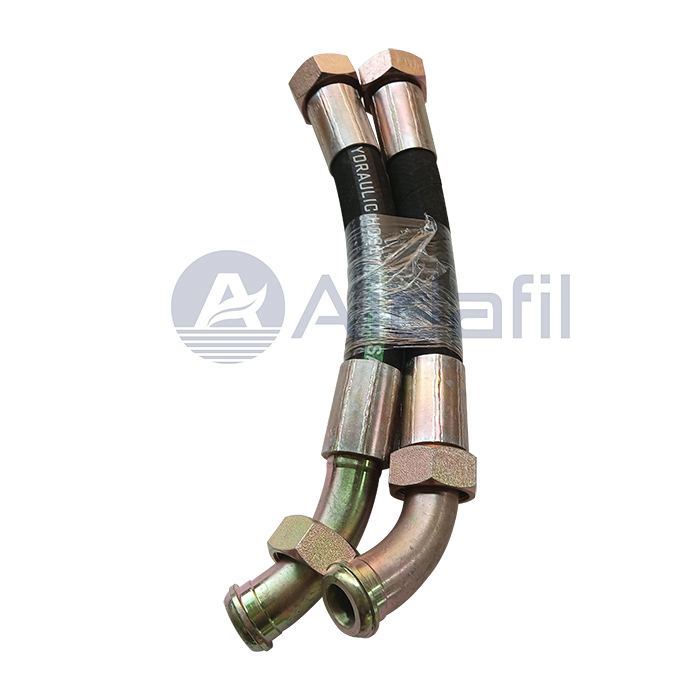

Hose assembly

Hose assembly

1614662600

(replacement)for Atlas Copco

Part numbers marked "replacement" are not affiliated with the original manufacture. Part numbers and pictures are used for cross reference only.

- Description

Atlas Copco Hose assembly 1614662600 replacement

The 1614662600 air compressor hose is precisely what its name suggests: a soft, bendable conduit typically made from polymer materials or reinforced fabrics. Within a compressed air system, it is entrusted with the task of transporting the compressed air generated by the machine to the point of use or connecting different components within the system. But why opt for a hose over a rigid pipe? The answer lies in its flexibility and adaptability; a hose can easily navigate complex installation environments, reduce the number of fittings, minimize the risk of leaks, and also facilitate maintenance and upgrades of the equipment.

The 1614662600 air compressor hose marks a critical component that connects an air compressor to various tools or machinery, facilitating the transfer of compressed air. Delving into its functional characteristics, the first to be highlighted is its exceptional flexibility. Like an athlete performing intricate moves in a gymnastics competition, a hose can bend and stretch in confined spaces or complex layouts, ensuring smooth and unobstructed airflow. Moreover, a quality hose possesses excellent pressure resistance, temperature tolerance, and anti-aging properties, standing like a seasoned soldier stable even in harsh working conditions.

When it comes to advantages, the use of the 1614662600 hose greatly simplifies the installation process. Imagine if rigid pipes were used, potentially requiring numerous fittings and supports, while a hose needs only one connection to the compressor and can reach the point of use directly—saving both time and effort. Also, by reducing the number of connections, it diminishes the potential for leaks, akin to a sturdy wall that defends against invaders, protecting the integrity of the system.

Features of the air compressor hose include:

1. The air compressor hose provides a flexible connection, simplifying the installation process, reducing installation time and costs. Additionally, hose connections help avoid stress concentration issues that may arise from rigid pipe connections.

2. The air compressor hose has excellent shock absorption properties, effectively reducing vibrations and noise generated during the transmission of compressed air, thereby improving equipment stability.

3. The air compressor hose possessed a certain degree of bending flexibility, enabling them to adapt to equipment displacement and vibrations during operation, minimizing stress effects.

4. The air compressor hose protects other equipment and components from wear and tear, extending their service life.

5. Depending on the usage environment, the air compressor hose with corrosion-resistant properties can be chosen to withstand corrosive media such as acids, alkalis, and oils.

Safety is paramount when using the air compressor hose. Regular inspections should be conducted to identify any signs of wear, damage, or leaks. Cracks, blisters, or abrasions on the hose's surface can indicate impending failure, necessitating immediate replacement. Additionally, it is vital to ensure that the hose's pressure rating matches the compressor's output and the connected tools' requirements to avoid overpressure, which could lead to catastrophic failure.

Proper storage and maintenance further enhance the longevity and safety of air compressor hoses. When not in use, hoses should be stored in a cool, dry place away from direct sunlight and ozone sources. They should be hung rather than coiled tightly, to prevent kinking and reduce stress on the material. Before use, it is advisable to inspect the hose for visible damage and perform a pressure test if necessary.

The Hose assembly is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our 1614662600 Hose assembly can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

The 1614662600 air compressor hose is precisely what its name suggests: a soft, bendable conduit typically made from polymer materials or reinforced fabrics. Within a compressed air system, it is entrusted with the task of transporting the compressed air generated by the machine to the point of use or connecting different components within the system. But why opt for a hose over a rigid pipe? The answer lies in its flexibility and adaptability; a hose can easily navigate complex installation environments, reduce the number of fittings, minimize the risk of leaks, and also facilitate maintenance and upgrades of the equipment.

The 1614662600 air compressor hose marks a critical component that connects an air compressor to various tools or machinery, facilitating the transfer of compressed air. Delving into its functional characteristics, the first to be highlighted is its exceptional flexibility. Like an athlete performing intricate moves in a gymnastics competition, a hose can bend and stretch in confined spaces or complex layouts, ensuring smooth and unobstructed airflow. Moreover, a quality hose possesses excellent pressure resistance, temperature tolerance, and anti-aging properties, standing like a seasoned soldier stable even in harsh working conditions.

When it comes to advantages, the use of the 1614662600 hose greatly simplifies the installation process. Imagine if rigid pipes were used, potentially requiring numerous fittings and supports, while a hose needs only one connection to the compressor and can reach the point of use directly—saving both time and effort. Also, by reducing the number of connections, it diminishes the potential for leaks, akin to a sturdy wall that defends against invaders, protecting the integrity of the system.

Features of the air compressor hose include:

1. The air compressor hose provides a flexible connection, simplifying the installation process, reducing installation time and costs. Additionally, hose connections help avoid stress concentration issues that may arise from rigid pipe connections.

2. The air compressor hose has excellent shock absorption properties, effectively reducing vibrations and noise generated during the transmission of compressed air, thereby improving equipment stability.

3. The air compressor hose possessed a certain degree of bending flexibility, enabling them to adapt to equipment displacement and vibrations during operation, minimizing stress effects.

4. The air compressor hose protects other equipment and components from wear and tear, extending their service life.

5. Depending on the usage environment, the air compressor hose with corrosion-resistant properties can be chosen to withstand corrosive media such as acids, alkalis, and oils.

Safety is paramount when using the air compressor hose. Regular inspections should be conducted to identify any signs of wear, damage, or leaks. Cracks, blisters, or abrasions on the hose's surface can indicate impending failure, necessitating immediate replacement. Additionally, it is vital to ensure that the hose's pressure rating matches the compressor's output and the connected tools' requirements to avoid overpressure, which could lead to catastrophic failure.

Proper storage and maintenance further enhance the longevity and safety of air compressor hoses. When not in use, hoses should be stored in a cool, dry place away from direct sunlight and ozone sources. They should be hung rather than coiled tightly, to prevent kinking and reduce stress on the material. Before use, it is advisable to inspect the hose for visible damage and perform a pressure test if necessary.

The Hose assembly is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our 1614662600 Hose assembly can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

Related products