Professional manufacturer and trader of air compressor parts

Whatsapp/Wechat+0086 15137376132

Replacement P85-250

Precision filter element

Precision filter element

P85-250

(replacement)for Parker

Part numbers marked "replacement" are not affiliated with the original manufacture. Part numbers and pictures are used for cross reference only.

- Description

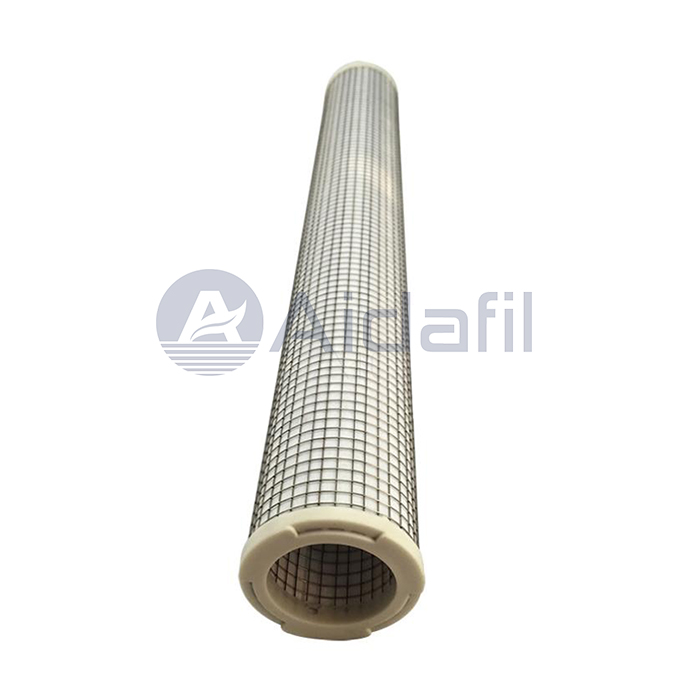

Parker Precision filter element P85-250 replacement

The P85-250 dust removal precision filter element, as the name suggests, is aimed to remove dust particles from compressed air systems. These contaminants can cause significant damage to the downstream components and equipment, leading to increased downtime and maintenance costs. The filter element is designed to ensure that the compressed air system operates at the highest level of efficiency, reducing the risk of equipment failure and increasing the lifespan of downstream components.

Specification

Filter element structure : String-wound filter element

End cap : ABS nylon

Working temperature : -10 ~ +80°C

Working medium : Clean, oil-free, neutral compressed air and industrial gas

Filter material : High quality fiber material

Frame : Carbon steel

Filtration rate : 1 μm

Flow rate : 56 Nm³/min

Working lifetime : 6000-8000h

Size : Standard

Usage : For compressed air system

Features

1. High-efficiency pleated media. The P85-250 filter element features a high-efficiency pleated media that provides a large surface area for capturing even the smallest particles. This media is designed to capture particles down to 1 micron in size, ensuring that the air supplied to the equipment is clean and free from contaminants.

2. Rigid frame support. The media is supported by a rigid frame that ensures the P85-250 filter element maintains its shape during operation, allowing for maximum efficiency and long life.

3. High flow capacity. The P85-250 filter element is designed to handle high flow rates while maintaining low pressure drop, ensuring that the compressed air system operates efficiently.

4. Easy installation. The P85-250 filter element is designed for easy installation and replacement, allowing for quick and simple maintenance.

Advantages and Benefits

The use of P85-250 dust removal precision filter element can bring a variety of advantages and benefits to enterprises.

1. Improve product quality - Pure compressed air helps ensure high-quality products.

2. Extend the service life of equipment - Reduce the wear of particulate matter on the internal components of the compressed air system.

3. Reduce maintenance costs - Reduce breakdowns and repair requirements due to impurities.

4. Improve production efficiency - A stable supply of compressed air is essential for the smooth running of the production process.

5. Meet environmental requirements - Reduce particulate matter emissions and comply with national and local environmental standards.

Application Scenarios

The P85-250 dust removal precision filter element finds applications across a wide range of industries:

1. Manufacturing facilities

It is suitable for use in various manufacturing processes, including metal fabrication, woodworking, plastics, textiles, and more. The P85-250 filter element ensures clean and reliable compressed air, minimizing the chances of product defects and equipment failures.

2. Pharmaceutical and healthcare

In pharmaceutical production facilities, laboratories, and hospitals, the P85-250 filter element maintains the required air purity levels, ensuring hygienic conditions and preventing contamination of sensitive products and environments.

3. Food and beverage

Compressed air is extensively used in the food and beverage industry for various operations, including packaging, bottling, and ingredient handling. The P85-250 filter element ensures the air used in these processes meets the stringent standards for food safety and quality.

4. Electronics and semiconductor manufacturing

Clean air is vital in electronics manufacturing to prevent damage to sensitive electronic components. The P85-250 filter element provides high-efficiency filtration, ensuring particle-free air in clean rooms and other controlled environments.

Precautions for Use

To ensure optimal performance and longevity of the P85-250 dust removal precision filter element, it is essential to adhere to the following precautions:

1. Regularly inspect the filter for damage or leaks and replace or repair as necessary.

2. Regularly clean or replace the filter element to maintain its efficiency and trap particles effectively.

3. Refer to the manufacturer's instructions and technical specifications for accurate installation and use.

4. Store and operate the filter in a clean environment to avoid introducing foreign particles or debris.

5. Handle with care during transportation to prevent excessive vibrations or impact that could damage the filter.

The Precision filter element is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our P85-250 Precision filter element can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

The P85-250 dust removal precision filter element, as the name suggests, is aimed to remove dust particles from compressed air systems. These contaminants can cause significant damage to the downstream components and equipment, leading to increased downtime and maintenance costs. The filter element is designed to ensure that the compressed air system operates at the highest level of efficiency, reducing the risk of equipment failure and increasing the lifespan of downstream components.

Specification

Filter element structure : String-wound filter element

End cap : ABS nylon

Working temperature : -10 ~ +80°C

Working medium : Clean, oil-free, neutral compressed air and industrial gas

Filter material : High quality fiber material

Frame : Carbon steel

Filtration rate : 1 μm

Flow rate : 56 Nm³/min

Working lifetime : 6000-8000h

Size : Standard

Usage : For compressed air system

Features

1. High-efficiency pleated media. The P85-250 filter element features a high-efficiency pleated media that provides a large surface area for capturing even the smallest particles. This media is designed to capture particles down to 1 micron in size, ensuring that the air supplied to the equipment is clean and free from contaminants.

2. Rigid frame support. The media is supported by a rigid frame that ensures the P85-250 filter element maintains its shape during operation, allowing for maximum efficiency and long life.

3. High flow capacity. The P85-250 filter element is designed to handle high flow rates while maintaining low pressure drop, ensuring that the compressed air system operates efficiently.

4. Easy installation. The P85-250 filter element is designed for easy installation and replacement, allowing for quick and simple maintenance.

Advantages and Benefits

The use of P85-250 dust removal precision filter element can bring a variety of advantages and benefits to enterprises.

1. Improve product quality - Pure compressed air helps ensure high-quality products.

2. Extend the service life of equipment - Reduce the wear of particulate matter on the internal components of the compressed air system.

3. Reduce maintenance costs - Reduce breakdowns and repair requirements due to impurities.

4. Improve production efficiency - A stable supply of compressed air is essential for the smooth running of the production process.

5. Meet environmental requirements - Reduce particulate matter emissions and comply with national and local environmental standards.

Application Scenarios

The P85-250 dust removal precision filter element finds applications across a wide range of industries:

1. Manufacturing facilities

It is suitable for use in various manufacturing processes, including metal fabrication, woodworking, plastics, textiles, and more. The P85-250 filter element ensures clean and reliable compressed air, minimizing the chances of product defects and equipment failures.

2. Pharmaceutical and healthcare

In pharmaceutical production facilities, laboratories, and hospitals, the P85-250 filter element maintains the required air purity levels, ensuring hygienic conditions and preventing contamination of sensitive products and environments.

3. Food and beverage

Compressed air is extensively used in the food and beverage industry for various operations, including packaging, bottling, and ingredient handling. The P85-250 filter element ensures the air used in these processes meets the stringent standards for food safety and quality.

4. Electronics and semiconductor manufacturing

Clean air is vital in electronics manufacturing to prevent damage to sensitive electronic components. The P85-250 filter element provides high-efficiency filtration, ensuring particle-free air in clean rooms and other controlled environments.

Precautions for Use

To ensure optimal performance and longevity of the P85-250 dust removal precision filter element, it is essential to adhere to the following precautions:

1. Regularly inspect the filter for damage or leaks and replace or repair as necessary.

2. Regularly clean or replace the filter element to maintain its efficiency and trap particles effectively.

3. Refer to the manufacturer's instructions and technical specifications for accurate installation and use.

4. Store and operate the filter in a clean environment to avoid introducing foreign particles or debris.

5. Handle with care during transportation to prevent excessive vibrations or impact that could damage the filter.

The Precision filter element is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our P85-250 Precision filter element can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

Related products