Professional manufacturer and trader of air compressor parts

Whatsapp/Wechat+0086 15137376132

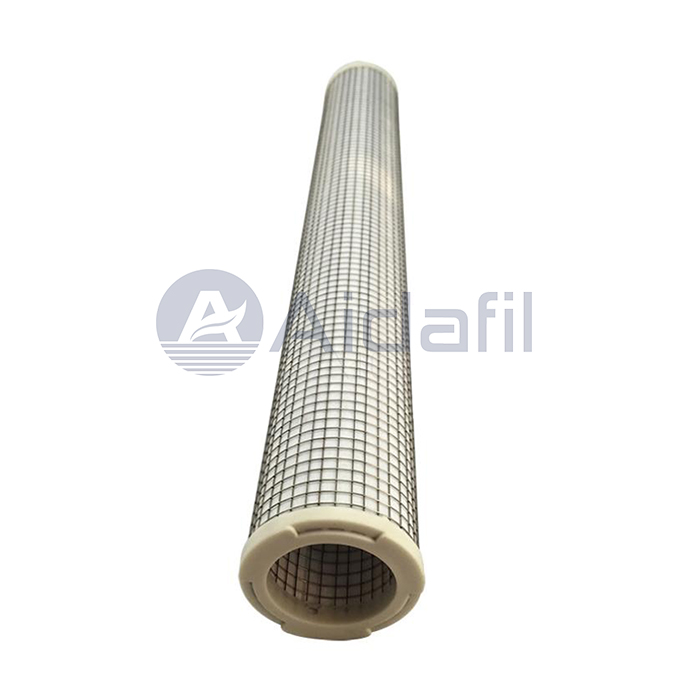

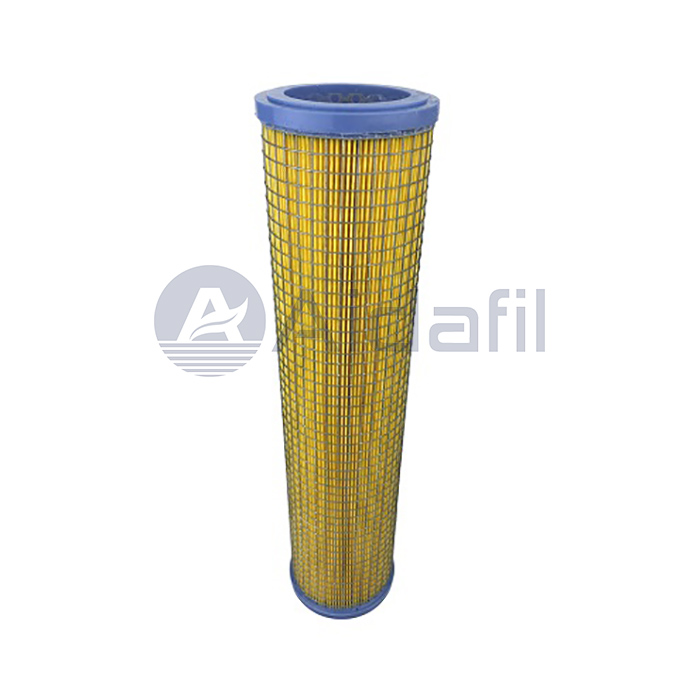

Replacement P25-130

Precision filter element

Precision filter element

P25-130

(replacement)for Parker

Part numbers marked "replacement" are not affiliated with the original manufacture. Part numbers and pictures are used for cross reference only.

- Description

Parker Precision filter element P25-130 replacement

The P25-130 precision filter element is a high-performance filtration component designed for removing contaminants from compressed air systems. This filter element plays a crucial role in ensuring the cleanliness and reliability of pneumatic equipment, which is essential in various industrial applications. It aims to remove dust and other particulate matter from compressed air systems. As compressed air passes through the filter element, the contaminants are trapped within the filter media, allowing only clean air to pass through. This process helps to protect downstream equipment from damage caused by contaminants and ensures the efficient operation of pneumatic systems.

Specification

Filter element structure : String-wound filter element

End cap : ABS nylon

Working temperature : -10 ~ +80°C

Working medium : Clean, oil-free, neutral compressed air and industrial gas

Filter material : High quality fiber material

Frame : Carbon steel

Filtration rate : 1 μm

Flow rate : 7 Nm³/min

Working lifetime : 6000-8000h

Size : Standard

Usage : For compressed air system

Features

1. High efficiency

The P25-130 filter element features a high-efficiency filter media that can capture even the smallest particles, ensuring exceptional filtration performance.

2. Long service life

Thanks to its robust construction and high-quality materials, the P25-130 filter element can withstand harsh operating conditions and provide an extended service life.

3. Easy installation and maintenance

The P25-130 filter element is designed for easy installation and replacement, minimizing downtime and maintenance costs.

4. Versatile compatibility

The P25-130 filter element is compatible with a wide range of compressed air systems, making it a versatile solution for various applications.

Benefits

1. Improved system performance

By removing contaminants from compressed air, the P25-130 filter element helps to improve the overall performance of pneumatic systems, reducing wear and tear on equipment and extending its lifespan.

2. Cost savings

The long service life and easy maintenance of the P25-130 filter element can help reduce maintenance costs and minimize downtime, resulting in significant cost savings for users.

3. Enhanced safety

Clean compressed air is essential for the safe operation of pneumatic equipment. By effectively removing contaminants, the P25-130 filter element helps to prevent accidents and ensure the safety of workers.

4. Environmental protection

The use of high-efficiency filter elements like the P25-130 can help reduce the release of contaminants into the environment, promoting sustainable practices in industrial operations.

Application

1. Manufacturing

In industries such as automotive, aerospace, and electronics manufacturing, clean compressed air is essential for ensuring the quality of products and preventing equipment damage.

2. Food and beverage production

The food and beverage industry requires strict hygiene standards, and the use of high-efficiency filter elements like the P25-130 can help ensure the cleanliness of compressed air used in production processes.

3. Medical and healthcare facilities

Clean compressed air is critical in medical and healthcare settings, where it is used for various purposes, such as powering medical equipment and maintaining sterile environments.

4. Construction and mining

Industrial applications in construction and mining often involve harsh operating conditions, making high-quality filter elements like the P25-130 essential for protecting pneumatic equipment from damage caused by contaminants.

Matters Needing Attention

1. Proper installation. Follow the manufacturer's guidelines for correct installation, including torque specifications and orientation of the filter element.

2. Regular maintenance. Implement a regular maintenance schedule to monitor and replace the filter element when necessary, based on pressure drop or specified intervals.

3. Operating conditions. Ensure that the operational parameters such as temperature, pressure, and airflow are within the recommended limits specified by the manufacturer.

4. Compatibility. Verify that the filter element is compatible with the compressed air system, taking into account the operating conditions, compatibility of materials, and the required filtration efficiency.

The Precision filter element is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our P25-130 Precision filter element can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

The P25-130 precision filter element is a high-performance filtration component designed for removing contaminants from compressed air systems. This filter element plays a crucial role in ensuring the cleanliness and reliability of pneumatic equipment, which is essential in various industrial applications. It aims to remove dust and other particulate matter from compressed air systems. As compressed air passes through the filter element, the contaminants are trapped within the filter media, allowing only clean air to pass through. This process helps to protect downstream equipment from damage caused by contaminants and ensures the efficient operation of pneumatic systems.

Specification

Filter element structure : String-wound filter element

End cap : ABS nylon

Working temperature : -10 ~ +80°C

Working medium : Clean, oil-free, neutral compressed air and industrial gas

Filter material : High quality fiber material

Frame : Carbon steel

Filtration rate : 1 μm

Flow rate : 7 Nm³/min

Working lifetime : 6000-8000h

Size : Standard

Usage : For compressed air system

Features

1. High efficiency

The P25-130 filter element features a high-efficiency filter media that can capture even the smallest particles, ensuring exceptional filtration performance.

2. Long service life

Thanks to its robust construction and high-quality materials, the P25-130 filter element can withstand harsh operating conditions and provide an extended service life.

3. Easy installation and maintenance

The P25-130 filter element is designed for easy installation and replacement, minimizing downtime and maintenance costs.

4. Versatile compatibility

The P25-130 filter element is compatible with a wide range of compressed air systems, making it a versatile solution for various applications.

Benefits

1. Improved system performance

By removing contaminants from compressed air, the P25-130 filter element helps to improve the overall performance of pneumatic systems, reducing wear and tear on equipment and extending its lifespan.

2. Cost savings

The long service life and easy maintenance of the P25-130 filter element can help reduce maintenance costs and minimize downtime, resulting in significant cost savings for users.

3. Enhanced safety

Clean compressed air is essential for the safe operation of pneumatic equipment. By effectively removing contaminants, the P25-130 filter element helps to prevent accidents and ensure the safety of workers.

4. Environmental protection

The use of high-efficiency filter elements like the P25-130 can help reduce the release of contaminants into the environment, promoting sustainable practices in industrial operations.

Application

1. Manufacturing

In industries such as automotive, aerospace, and electronics manufacturing, clean compressed air is essential for ensuring the quality of products and preventing equipment damage.

2. Food and beverage production

The food and beverage industry requires strict hygiene standards, and the use of high-efficiency filter elements like the P25-130 can help ensure the cleanliness of compressed air used in production processes.

3. Medical and healthcare facilities

Clean compressed air is critical in medical and healthcare settings, where it is used for various purposes, such as powering medical equipment and maintaining sterile environments.

4. Construction and mining

Industrial applications in construction and mining often involve harsh operating conditions, making high-quality filter elements like the P25-130 essential for protecting pneumatic equipment from damage caused by contaminants.

Matters Needing Attention

1. Proper installation. Follow the manufacturer's guidelines for correct installation, including torque specifications and orientation of the filter element.

2. Regular maintenance. Implement a regular maintenance schedule to monitor and replace the filter element when necessary, based on pressure drop or specified intervals.

3. Operating conditions. Ensure that the operational parameters such as temperature, pressure, and airflow are within the recommended limits specified by the manufacturer.

4. Compatibility. Verify that the filter element is compatible with the compressed air system, taking into account the operating conditions, compatibility of materials, and the required filtration efficiency.

The Precision filter element is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our P25-130 Precision filter element can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

Related products