Professional manufacturer and trader of air compressor parts

Whatsapp/Wechat+0086 15137376132

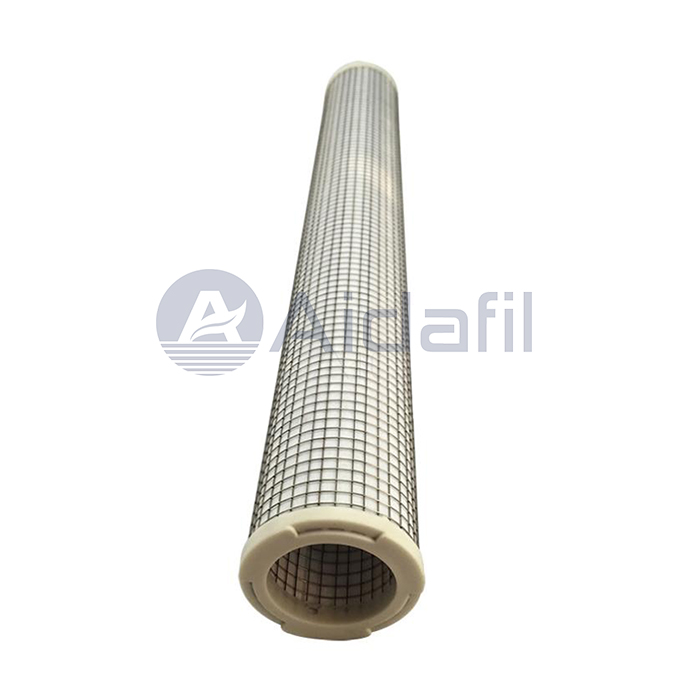

Replacement C15-60

Precision filter element

Precision filter element

C15-60

(replacement)for Parker

Part numbers marked "replacement" are not affiliated with the original manufacture. Part numbers and pictures are used for cross reference only.

- Description

Parker Precision filter element C15-60 replacement

The C15-60 compressed air precision filter element is designed to remove oil and other contaminants from compressed air lines. It does this by separating the oil droplets from the air stream and collecting them in a filter element. The filter element is then removed and replaced as needed. This ensures that the compressed air remains clean and free of harmful contaminants, which can damage equipment if inhaled.

By ensuring the delivery of clean compressed air, this filter element enhances equipment life, product quality, energy efficiency, and environmental compliance.

Specification

Filter element structure : String-wound filter element

End cap : ABS nylon

Working temperature : -10 ~ +80°C

Working medium : Clean, oil-free, neutral compressed air and industrial gas

Filter material : High quality fiber material

Frame : Carbon steel

Filtration accuracy : 0.01 μm

Residual oil content : 0.01 ppm

Flow rate : 2.8 Nm³/min

Working lifetime : 6000-8000h

Size : Standard

Usage : For compressed air system

Features

1. High filtration efficiency. The C15-60 filter element effectively removes oil and particulate contaminants down to 0.01 microns, ensuring exceptional air purity.

2. Durable construction. Made from high-quality materials, the C15-60 filter element offers excellent durability and longevity, even in demanding operating conditions.

3. Low pressure drop. The design of the C15-60 filter element minimizes pressure drop, optimizing energy efficiency and reducing operational costs.

4. Easy replacement. The C15-60 filter element is designed for convenient and quick replacement, minimizing system downtime during maintenance.

Advantages

1. Enhanced equipment Life. By effectively removing oil and solid contaminants, the C15-60 filter element extends the lifespan of downstream equipment, reducing maintenance and replacement costs.

2. Improved product quality. Clean compressed air prevents contamination in sensitive applications such as food and beverage, pharmaceuticals, electronics, and automotive industries, ensuring product quality and compliance with regulatory standards.

3. Energy efficiency. The low-pressure drop feature of the C15-60 filter element reduces energy consumption, minimizing operational costs over time.

4. Environmental compliance. The C15-60 filter element aids in maintaining a clean working environment by preventing oil and particulate emissions, promoting sustainability practices.

Application

The C15-60 is suitable for use in a wide range of applications, including manufacturing, automotive, food processing, and healthcare. In manufacturing, it can be used to ensure that compressed air remains clean and free of contaminants, preventing damage to equipment and reducing downtime. In automotive, it can be used to ensure that paint booths remain clean and free of oil particles, ensuring high-quality finishes. In food processing, it can be used to ensure that compressed air remains clean and free of contaminants, preventing contamination of food products. In healthcare, it can be used to ensure that medical equipment remains clean and free of contaminants, preventing health risks to patients.

Precautions

1. Proper and timely maintenance, including filter replacement, is crucial to ensure the long-term effectiveness of the filter element and system performance.

2. The filter element should be used within specified temperature, pressure, and humidity ranges to ensure optimal performance and longevity.

3. Properly sizing the filter element based on the compressed air system's flow rate and pressure is essential for efficient operation and effective contamination removal.

4. Following the manufacturer's instructions for installation, usage, and maintenance is vital to guarantee the filter element's performance and avoid potential risks.

We value customer cooperation and provides technical support, product training, and customized solutions to meet specific requirements. We offer comprehensive customer service, assisting in installation, maintenance, and troubleshooting of the filter element. This collaborative approach ensures optimal performance and customer satisfaction.

The Precision filter element is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our C15-60 Precision filter element can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

The C15-60 compressed air precision filter element is designed to remove oil and other contaminants from compressed air lines. It does this by separating the oil droplets from the air stream and collecting them in a filter element. The filter element is then removed and replaced as needed. This ensures that the compressed air remains clean and free of harmful contaminants, which can damage equipment if inhaled.

By ensuring the delivery of clean compressed air, this filter element enhances equipment life, product quality, energy efficiency, and environmental compliance.

Specification

Filter element structure : String-wound filter element

End cap : ABS nylon

Working temperature : -10 ~ +80°C

Working medium : Clean, oil-free, neutral compressed air and industrial gas

Filter material : High quality fiber material

Frame : Carbon steel

Filtration accuracy : 0.01 μm

Residual oil content : 0.01 ppm

Flow rate : 2.8 Nm³/min

Working lifetime : 6000-8000h

Size : Standard

Usage : For compressed air system

Features

1. High filtration efficiency. The C15-60 filter element effectively removes oil and particulate contaminants down to 0.01 microns, ensuring exceptional air purity.

2. Durable construction. Made from high-quality materials, the C15-60 filter element offers excellent durability and longevity, even in demanding operating conditions.

3. Low pressure drop. The design of the C15-60 filter element minimizes pressure drop, optimizing energy efficiency and reducing operational costs.

4. Easy replacement. The C15-60 filter element is designed for convenient and quick replacement, minimizing system downtime during maintenance.

Advantages

1. Enhanced equipment Life. By effectively removing oil and solid contaminants, the C15-60 filter element extends the lifespan of downstream equipment, reducing maintenance and replacement costs.

2. Improved product quality. Clean compressed air prevents contamination in sensitive applications such as food and beverage, pharmaceuticals, electronics, and automotive industries, ensuring product quality and compliance with regulatory standards.

3. Energy efficiency. The low-pressure drop feature of the C15-60 filter element reduces energy consumption, minimizing operational costs over time.

4. Environmental compliance. The C15-60 filter element aids in maintaining a clean working environment by preventing oil and particulate emissions, promoting sustainability practices.

Application

The C15-60 is suitable for use in a wide range of applications, including manufacturing, automotive, food processing, and healthcare. In manufacturing, it can be used to ensure that compressed air remains clean and free of contaminants, preventing damage to equipment and reducing downtime. In automotive, it can be used to ensure that paint booths remain clean and free of oil particles, ensuring high-quality finishes. In food processing, it can be used to ensure that compressed air remains clean and free of contaminants, preventing contamination of food products. In healthcare, it can be used to ensure that medical equipment remains clean and free of contaminants, preventing health risks to patients.

Precautions

1. Proper and timely maintenance, including filter replacement, is crucial to ensure the long-term effectiveness of the filter element and system performance.

2. The filter element should be used within specified temperature, pressure, and humidity ranges to ensure optimal performance and longevity.

3. Properly sizing the filter element based on the compressed air system's flow rate and pressure is essential for efficient operation and effective contamination removal.

4. Following the manufacturer's instructions for installation, usage, and maintenance is vital to guarantee the filter element's performance and avoid potential risks.

We value customer cooperation and provides technical support, product training, and customized solutions to meet specific requirements. We offer comprehensive customer service, assisting in installation, maintenance, and troubleshooting of the filter element. This collaborative approach ensures optimal performance and customer satisfaction.

The Precision filter element is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our C15-60 Precision filter element can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

Related products