Professional manufacturer and trader of air compressor parts

Whatsapp/Wechat+0086 15137376132

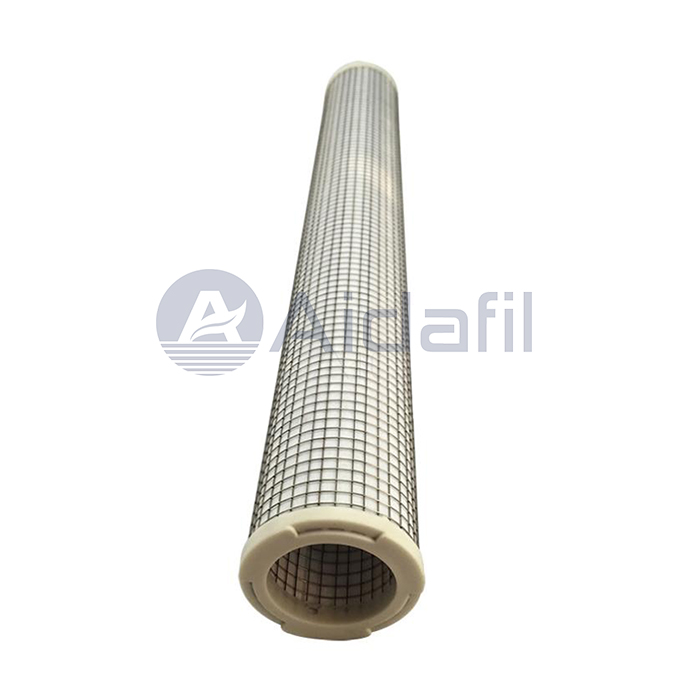

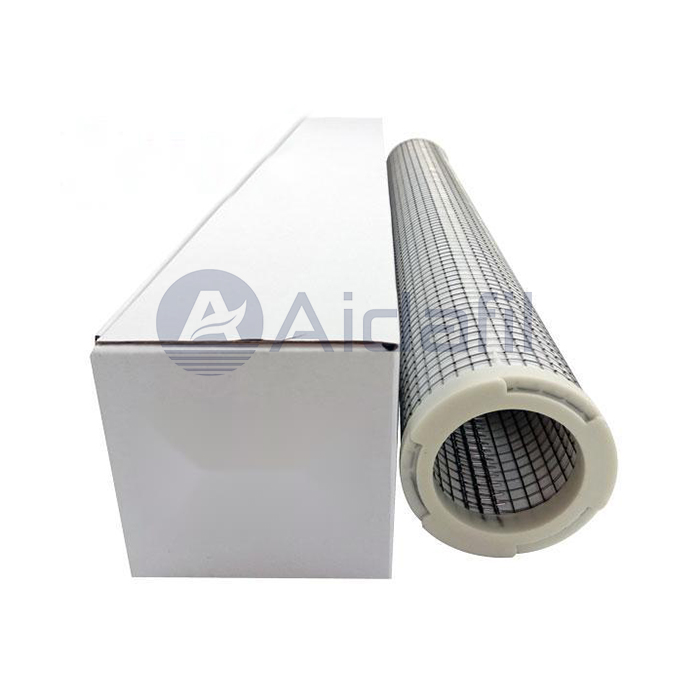

Replacement C10-50

Precision filter element

Precision filter element

C10-50

(replacement)for Parker

Part numbers marked "replacement" are not affiliated with the original manufacture. Part numbers and pictures are used for cross reference only.

- Description

Parker Precision filter element C10-50 replacement

C10-50 compressed air precision filter element, a top-quality oil removal filter element, plays a critical role in maintaining clean and contaminant-free compressed air systems. It is a highly efficient component designed to eliminate oil and other contaminants from compressed air systems. From the functional point of view, the C10-50 filter element is responsible for removing oil aerosols and solid contaminants from compressed air systems. It ensures that the air supplied is clean, meeting the stringent quality requirements of different applications. By efficiently separating oil and solid particles, the filter element prevents damage to downstream equipment, thereby enhancing the overall system performance and reliability. It is compact in size and therefore it is easy to install and replace.

Specification

Filter element structure : String-wound filter element

End cap : ABS nylon

Working temperature : -10 ~ +80°C

Working medium : Clean, oil-free, neutral compressed air and industrial gas

Filter material : High quality fiber material

Frame : Carbon steel

Filtration accuracy : 0.01 μm

Residual oil content : 0.01 ppm

Flow rate : 1.4 Nm³/min

Working lifetime : 6000-8000h

Size : Standard

Usage : For compressed air system

Advantages

1. Enhanced equipment longevity

By effectively removing oil contaminants, the C10-50 filter element significantly extends the lifespan of downstream equipment. It prevents oil-related issues such as clogging, corrosion, and increased wear and tear, ensuring reliable and durable operation.

2. Improved product quality

Oil-contaminated air can negatively impact the quality of end products, leading to rejections and customer dissatisfaction. By using the C10-50 filter element, manufacturers can ensure consistent product quality, meeting or exceeding customer expectations.

3. Energy efficiency

Oil-free compressed air improves energy efficiency by reducing friction and minimizing heat buildup in machinery. This results in lower energy consumption, leading to cost savings and environmental benefits.

Applications

The C10-50 filter element finds extensive usage in various industries, including:

1. Manufacturing

It is employed in pneumatic tools, air-operated machinery, and production lines to ensure clean compressed air supply, enhancing operational efficiency and product quality.

2. Food and Beverage

The filter element is crucial to prevent oil contamination in compressed air used for food processing, packaging, and storage, complying with stringent hygiene regulations.

3. Pharmaceuticals

Clean compressed air is essential for maintaining sterile environments in pharmaceutical manufacturing processes, preventing product contamination and complying with industry standards.

4. Electronics

The filter element is utilized in electronics manufacturing to remove oil and solid particles, safeguarding sensitive components from damage and ensuring product reliability.

5. Automotive

It is widely employed in automotive manufacturing, painting booths, and assembly lines to eliminate oil contaminants, preventing defects and ensuring high-quality finishes.

Matters Needing Attention

While the C10-50 compressed air precision filter element offers exceptional performance, some factors require attention when using it:

1. Proper maintenance

Regular maintenance and timely replacement of the filter element are essential to ensure optimal filtration efficiency. Neglecting maintenance can result in reduced performance and potential equipment damage.

2. System pressure monitoring

Continuous monitoring of system pressure helps identify any abnormalities that may indicate the need for filter element replacement or system maintenance. Timely action helps maintain consistent airflow and prevents unnecessary downtime.

3. Correct sizing

Selecting the appropriate filter element size based on the compressed air system's flow rate is crucial for optimum performance. Proper sizing ensures efficient filtration without excessive pressure drop.

Our company values customer satisfaction and strives to build strong cooperative relationships. The company provides comprehensive technical support, assisting customers in selecting the appropriate filter element for their specific application needs. Ongoing customer feedback is welcomed to drive continuous improvement and ensure that our solutions meet evolving industry requirements.

The Precision filter element is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our C10-50 Precision filter element can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

C10-50 compressed air precision filter element, a top-quality oil removal filter element, plays a critical role in maintaining clean and contaminant-free compressed air systems. It is a highly efficient component designed to eliminate oil and other contaminants from compressed air systems. From the functional point of view, the C10-50 filter element is responsible for removing oil aerosols and solid contaminants from compressed air systems. It ensures that the air supplied is clean, meeting the stringent quality requirements of different applications. By efficiently separating oil and solid particles, the filter element prevents damage to downstream equipment, thereby enhancing the overall system performance and reliability. It is compact in size and therefore it is easy to install and replace.

Specification

Filter element structure : String-wound filter element

End cap : ABS nylon

Working temperature : -10 ~ +80°C

Working medium : Clean, oil-free, neutral compressed air and industrial gas

Filter material : High quality fiber material

Frame : Carbon steel

Filtration accuracy : 0.01 μm

Residual oil content : 0.01 ppm

Flow rate : 1.4 Nm³/min

Working lifetime : 6000-8000h

Size : Standard

Usage : For compressed air system

Advantages

1. Enhanced equipment longevity

By effectively removing oil contaminants, the C10-50 filter element significantly extends the lifespan of downstream equipment. It prevents oil-related issues such as clogging, corrosion, and increased wear and tear, ensuring reliable and durable operation.

2. Improved product quality

Oil-contaminated air can negatively impact the quality of end products, leading to rejections and customer dissatisfaction. By using the C10-50 filter element, manufacturers can ensure consistent product quality, meeting or exceeding customer expectations.

3. Energy efficiency

Oil-free compressed air improves energy efficiency by reducing friction and minimizing heat buildup in machinery. This results in lower energy consumption, leading to cost savings and environmental benefits.

Applications

The C10-50 filter element finds extensive usage in various industries, including:

1. Manufacturing

It is employed in pneumatic tools, air-operated machinery, and production lines to ensure clean compressed air supply, enhancing operational efficiency and product quality.

2. Food and Beverage

The filter element is crucial to prevent oil contamination in compressed air used for food processing, packaging, and storage, complying with stringent hygiene regulations.

3. Pharmaceuticals

Clean compressed air is essential for maintaining sterile environments in pharmaceutical manufacturing processes, preventing product contamination and complying with industry standards.

4. Electronics

The filter element is utilized in electronics manufacturing to remove oil and solid particles, safeguarding sensitive components from damage and ensuring product reliability.

5. Automotive

It is widely employed in automotive manufacturing, painting booths, and assembly lines to eliminate oil contaminants, preventing defects and ensuring high-quality finishes.

Matters Needing Attention

While the C10-50 compressed air precision filter element offers exceptional performance, some factors require attention when using it:

1. Proper maintenance

Regular maintenance and timely replacement of the filter element are essential to ensure optimal filtration efficiency. Neglecting maintenance can result in reduced performance and potential equipment damage.

2. System pressure monitoring

Continuous monitoring of system pressure helps identify any abnormalities that may indicate the need for filter element replacement or system maintenance. Timely action helps maintain consistent airflow and prevents unnecessary downtime.

3. Correct sizing

Selecting the appropriate filter element size based on the compressed air system's flow rate is crucial for optimum performance. Proper sizing ensures efficient filtration without excessive pressure drop.

Our company values customer satisfaction and strives to build strong cooperative relationships. The company provides comprehensive technical support, assisting customers in selecting the appropriate filter element for their specific application needs. Ongoing customer feedback is welcomed to drive continuous improvement and ensure that our solutions meet evolving industry requirements.

The Precision filter element is a part of the air compressor. If this part is missing, it may affect the normal operation of the air compressor. AIDA provides high-quality alternatives. The quality and performance of our C10-50 Precision filter element can perfectly replace OEM original products. Compared with OEM, our products have the same performance and lower price. For customers who purchase our products, we provide perfect after-sales service. We believe you will be satisfied with our service. Contact us today!

Related products